What is CNC machining?

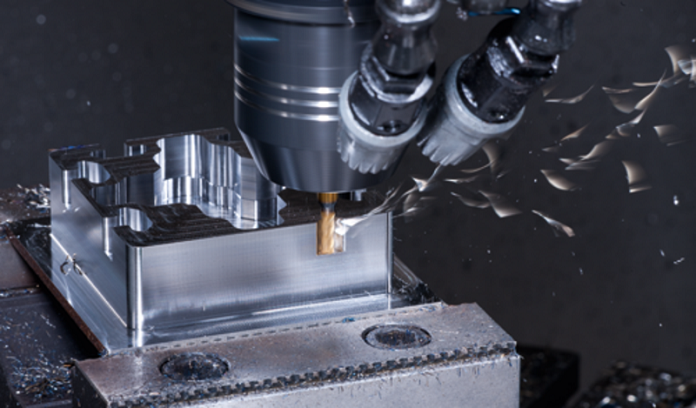

CNC machining is a tool used by manufacturing businesses and companies. CNC machining can be defined as the use of a pre-programmed computer which dictates the movement of tools required for manufacturing various goods and tools required to control machinery.

CNC stands for computer numerical control and it eliminates the requirement of manual control. What is more, that CNC machining also avoids the errors that can be made due to manual labor.

In essence, CNC machining works similar to a robot. To the eyes of an onlooker, the computer processes could not be that different from any other machine. In reality, the process of CNC machining is extremely different from other kinds of machine processing.

CNC machining makes use of precise dimensions and precise instructions to work. The desired cuts to be attained by the program are fed into the computer, down to the last detail and then the process is initiated.

Importance of CNC machining

Understanding the concept of CNC Auto Parts will help you to make sure that your manufacturing business runs well. Here is a list of reasons as to why CNC machining is important:

- Better than Manual Labor: Since CNC machining is fully automated, the procedure does away with the errors of manual labor. Cutting and making precise cuts is hard for manual labor and there is always a chance of error. However, CNC machining is programmed with exact details, which helps the program to offer correct measurements.

- Improved efficiency: As it was in manual labor, the production speed could be slow. Depending on how fast your laborers work, the speed of manufacturing could be determined. However, with the CNC machining, since all of your procedures are automated, the speed of manufacturing increases, which helps you to increase your business’s efficiency.

- Enhanced productivity: Since there is hardly any scope for manual error and everything is automated, your businesse’s productivity improves drastically. You can find the correct speed and precision in your products without worrying about anything. Additionally, since all of it is automated, the productivity of your business also increases as your losses decrease as well.

- Better Accuracy: CNC machining is all about automation. Since this procedure runs solely based on your computer program, your manufacturing process will be able to produce precise goods. You will not have to worry about mismatching dimensions. Additionally, this saves a lot of time as you do not have to spend time measuring each and every product produced for dimensions.

- Better Safety: As CNC machines do not require to be operated manually, your employees will be away from sharp tools. Since your employees will not be direct contact with the tools, factory accidents will decrease as well.

Apart from this, there are some advantages to be gained after you start making use of CNC machining and they are:

- Reduced set-up changes over time,

- Flexible manufacturing,

- Design retention,

- Low maintenance, and

- Accuracy, even when designing something complex.

CNC machining has changed the face of manufacturing businesses and has helped in improving the efficiency of the businesses.