Introduction

CNC machining, or Computer Numerical Control machining, is a modern manufacturing technique. It’s changed how things are made.

It’s quite different from older methods, and it brings a lot of benefits like better precision, faster work, and more automation.

Thus, we’ll look at what sets CNC machining apart from traditional methods. We’ll see how it’s unique and what its advantages are to manufacturing.

Understanding these differences helps us see how CNC turned components are shaping the future of manufacturing.

Understanding Traditional Machining

Conventional machining encompasses traditional methods for removing and shaping materials in manufacturing.

Techniques like turning, milling, drilling, grinding, and sawing fall under this category.

Skilled machinists use their hands to control machine tools. They change how the tools cut based on what they’ve learned to shape the material according to what’s needed.

These old-school methods are crucial for making parts, but they need skilled people to tweak them as they work. They’re good but not precise, repeatable, and automated like CNC turning parts.

But introducing CNC machining has changed manufacturing completely.

What is CNC Machining?

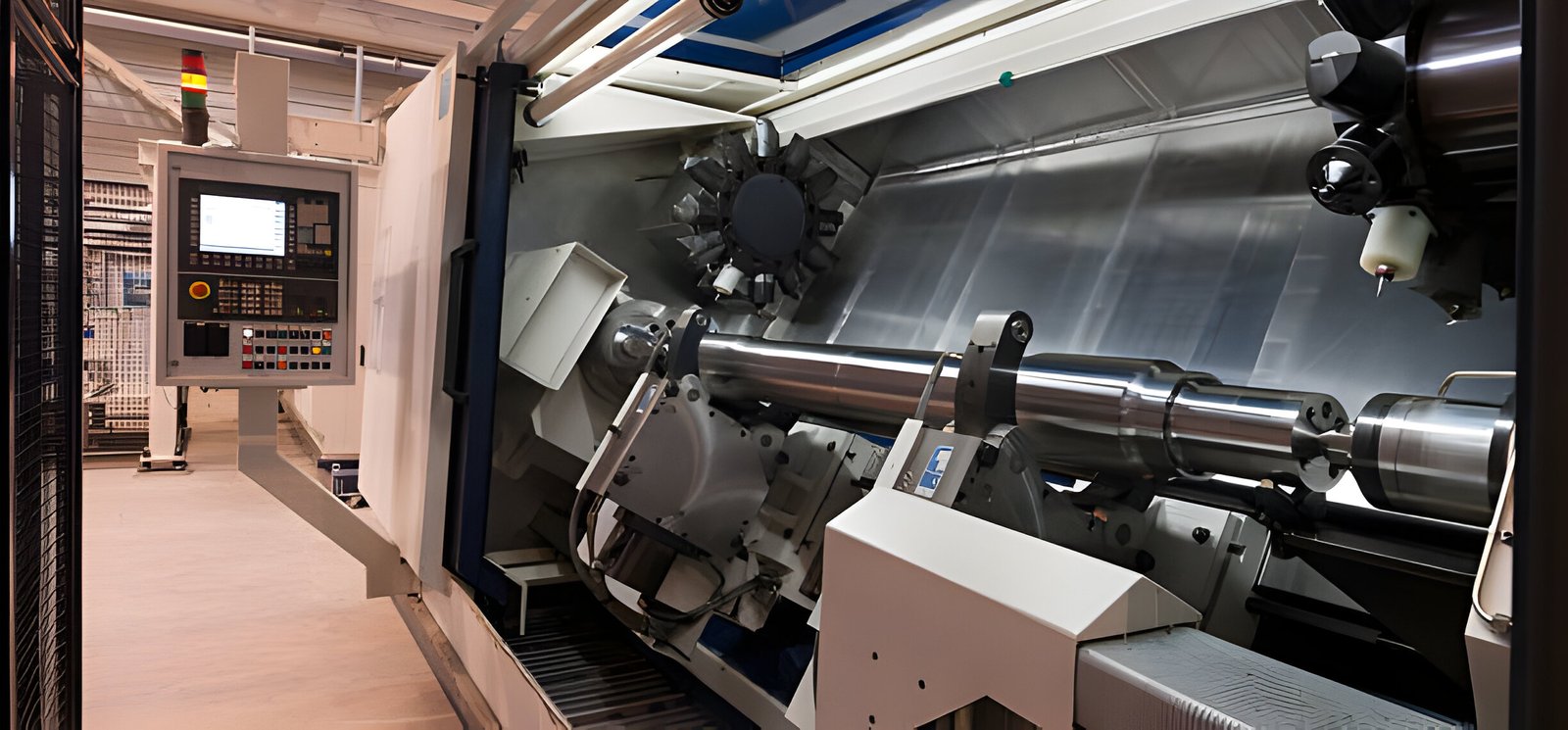

CNC machining, short for computer numerical control machining. It is a high-tech method of crafting parts and components.

Unlike manual operation of machine tools, computers oversee them. It ensures accuracy and efficiency in production, showing the CNC and NC difference.

Here’s how it works: Designers use computer programs. They often use CAD software to design the part and give instructions on how to make it.

These instructions are then turned into a special code called G-code, which the CNC machine understands.

The CNC machine follows this code to control its tools. It controls tools like mills, lathes, routers, and grinders.

It does this with precision, shaping the material and adding features and dimensions.

Difference Between CNC Machine and Traditional Machine

| Features | CNC Machine |

Traditional Machine |

|

Control Mechanism |

Computer-controlled | Manually operated |

| Accuracy | High |

Moderate to High |

|

Flexibility |

High | Limited |

| Setup Time | Longer |

Shorter |

|

Operator Skill Required |

Moderate | High |

| Reproducibility | High |

Moderate |

|

Production Rate |

Moderate to High | Moderate |

| Automation | Fully or Partially Automated |

Manual Operation |

|

Material Wastage |

Low |

Moderate to High |

Major Benefits of CNC Machining Compared to Traditional Machining

1. Effectiveness

CNC machining boosts production efficiency compared to traditional methods. Once set up, the CNC machine can keep working without needing constant attention. This leads to faster manufacturing and higher productivity.

Traditional machining demands manual operation, consuming significant time and effort. In contrast, CNC machining automates tasks through computer programming.

Once programmed, the NC CNC machine operates continuously, minimizing manual intervention. This automation accelerates production, enabling operators to concentrate on vital tasks.

In terms of production speed, CNC machining outpaces traditional methods. CNC machines can perform milling at high speeds without sacrificing accuracy.

This shortens cycle times and increases output. Also, CNC machines can perform multiple operations either at the same time or in sequence.

This further cuts down on production time.

2. Outstanding accuracy

NC machine delivers exceptional accuracy and precision when making parts and components. With CNC machining, the computer ensures consistent machine tool movements.

This gives us accurate and consistent results. Achieving this level of precision is challenging.

CNC machining achieves precision through accurate computer-controlled operations. The CNC program guides machine tools accurately.

It reduces human error in manual machining by directing machines along programmed paths. It also leads to improved dimensional accuracy.

Moreover, CNC machining can achieve tight tolerances, which are difficult with traditional methods.

The computer system controls cutting, feeds, and tool positions precisely. This enables the creation of intricate features with high accuracy and repeatability.

3. Reliability

Traditionally, people imagine busy factories with workers operating machines. But CNC technology has changed this view, challenging the old idea of manufacturing plants.

Unlike traditional setups, CNC turned components factory will require fewer workers to operate efficiently.

Operators and programmers are vital for handling various aspects of CNC production. This includes machine setup, programming, and quality control.

CNC technology depends on skilled individuals for efficient and precise production. Operators set up machines, monitor operations, and solve problems. Programmers create and improve CNC programs for the best results.

CNC technology simplifies manufacturing, boosts efficiency, and reduces manual work.

This not only improves productivity but also lets skilled workers focus on different tasks.

So, CNC changes how factories look and what workers do there.

4. Saves Time and Money

CNC machining brings big savings over time, even though setting up and programming take a bit at first. But once set, these machines run smoothly, saving a lot of time and money in the long run.

One of the primary advantages of CNC machining is the reduction in labor costs. Once programmed, these machines work independently.

This cuts down on manual labor and saving costs. Their precision also reduces material waste, adding to these savings.

Also, CNC machining often combines several steps into one process, saving time and resources.

Despite initial setup costs, CNC machining offers long-term advantages. These benefits make CNC machining a smart choice for manufacturers.

5. Reliable and Low-Maintenance

Workers’ compensation claims from factories can really affect both workers and bosses. To make the workplace safer and prevent injuries, using CNC machines in manufacturing is a smart move.

CNC machines cut down on accidents by doing most of the work automatically, so there’s less chance for mistakes.

That means fewer injuries from things like slips or lifting heavy stuff. So, bringing in CNC machines not only makes work easier but also keeps everyone safer.

When machines like CNC ones handle the work, they do it exactly the same way every time, which means workers don’t have to do risky tasks themselves.

This reduces accidents from slipping, tripping, or mishandling equipment.

Also, NC machine makes the workplace safer by reducing the strain on workers from doing the same tasks over and over or lifting heavy things.

Since the machines do most of the work, employees are less likely to get hurt.

Conclusion

CNC turning parts have a lot of advantages over old-school methods. It helps get more done with better accuracy and quality while also saving money.

With CNC machines, milling is done automatically, which means fewer mistakes and less need for people to step in. The machines make sure each part is just right every time, without variation.

CNC machining also cuts down on wasted materials, makes the most of tools, and lets you try out different designs easily.

All of this means less spending on labor, materials, tools, and quality checks. In simple terms, CNC machining is a game-changer for manufacturing, making things faster, cheaper, and more precise.

Ganesh Precision: Leading CNC-Turned Parts Manufacturer

Ganesh Precision is a leading manufacturer specializing in CNC turning parts. Ganesh Precision is dedicated to making high-quality components for industries worldwide.

Our advanced facility and skilled team guarantee precise products that meet each client’s needs.

Ganesh Precision is a trusted name in manufacturing. We’re known for our commitment to quality and customer satisfaction.

Our commitment to improvement and modern technology makes us the top choice for businesses.

We are the preferred choice for those seeking quality CNC machining solutions. Trust Ganesh Precision for precision, reliability, and excellence in CNC turned components manufacturing.