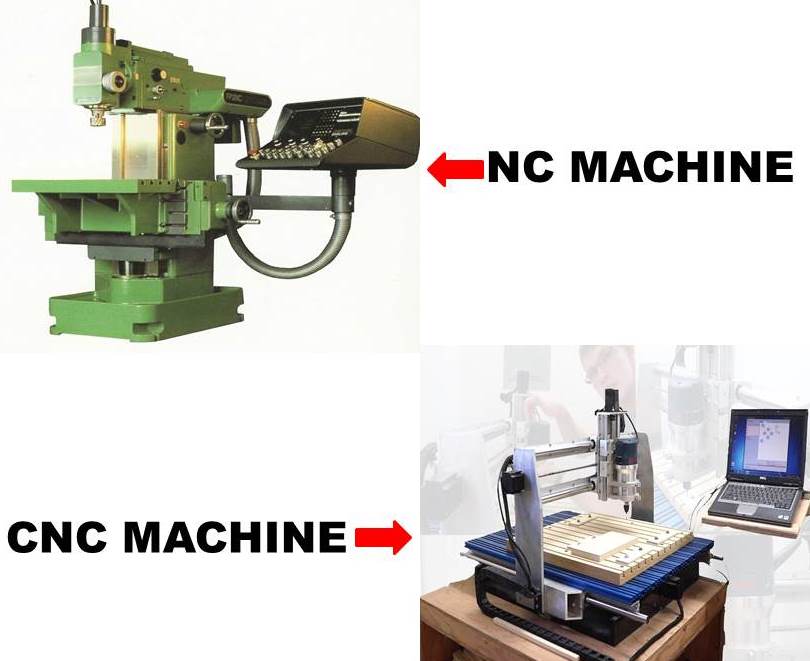

CNC and NC are both automatic machines used for machining any metal with accurate dimensions. These machines work on the feeding mechanism in which we command the machine through the program to make it perform a certain operation. To know more about these machines, read the difference between NC and CNC machine given below :

- NC stands for Numerical Control while CNC stands for Computer Numerical Control. NC machine is the machine that is controlled by a set of instructions in the form of numbers, letters, and symbols called a program. CNC machine is used to control motions of the workpiece and tool with a computer program written in alphanumeric data. The program consists of precise instructions about the manufacturing method as well as the movements.

- In the NC machine, programs are fed into the punch cards. In a CNC machine, the programs are fed directly into the computer using a small keyboard.

- It is very difficult to modify the program in NC machine if some error occurs and debugging is needed. In a CNC machine, modification of the program is very easy. For NC machines, you will have to change the program in the tape and feed it to the machine again even for a tiny change. In a CNC machine, you just have to change a variable in the computer to modify the program. This machine has memory storage and programs can be stored in its control.

- To operate an NC machine, the high skilled operator is required. For a CNC machine, the less skilled operator will work.

- Maintenance cost is less for NC machine is less as compared CNC machines. You can purchase CNC auto parts in Mumbai for reasonable prices.

- In NC machines, the programs cannot be stored. Whereas in CNC machines, the programs can be stored in the computer and can be used again and again.

- NC machine has no memory storage and it runs off of the tape each time the machine cycles. NC machines have a controller known as Machine Control Unit or MCU that is capable of reading and interpreting a stored program and using the instructions in this to control a machine via actuation devices.

- NC machines offer less flexibility and computational capability. CNC machines offer additional flexibility and computational capability.

- The accuracy of the NC machine is less as compared to CNC.

- On NC machines, more time is consumed for the execution of the job while it takes less time on CNC machines for the execution of the job.

- It is not possible to run NC machine continuously but you can run CNC machine continuously for 24 hours a day. CNC auto parts in Mumbai are easily available.

- Cost of NC machine is less while cost of CNC machines are very high.

FAQ

1What does the term “NC” stand for in CNC machining?

NC, which stands for Numerical Control, refers to a machine controlled by a specific set of instructions conveyed in the form of numbers, letters, and symbols contained within a program. On the other hand, CNC, short for Computer Numerical Control, involves the use of computer programs composed of alphanumeric data to govern the movements of both the workpiece and the tool. This program comprises meticulous instructions outlining the manufacturing process and the associated mechanical actions.

2What are the distinct types of NC and CNC systems available in manufacturing?

CNC Machine with Automatic Tool Changes, Grinding CNC Machine, Electric Discharge CNC Machine, Laser Cutting CNC Machine, Plasma Cutting CNC Machine, Milling CNC Machine, 5-Axis CNC Machine, Router CNC Machine are the distinct types of NC and CNC systems available in manufacturing.

3What benefits does CNC offer compared to NC?

When considering the integration of CNC machines into your production workflow, it’s essential to weigh the following factors: Minimal Expertise or Skills Required: You can operate CNC machinery effectively without demanding, specialized expertise. Streamlined Replication of Products: CNC technology facilitates the effortless replication of products on a large scale, making mass production more accessible. Reduced Labor Demands: Operating CNC machinery typically requires less manual labor, contributing to operational efficiency. Expanded Production Capabilities: The utilization of CNC software broadens your range of production possibilities, enhancing versatility in manufacturing.

4How do CNC (Computer Numerical Control), NC (Numerical Control), and DNC (Direct Numerical Control) systems differ from each other?

NC, or Numerical Control, relies on punch tapes and tape readers for machine programming. CNC, or Computer Numerical Control, utilizes computer-based code programming and a machine controller unit to interpret the code for the machine. DNC, which stands for Distributed Numerical Control, establishes a network linking numerous CNC machines to a central mainframe computer.