Introduction

Precision is a key factor in machining, as it guarantees accuracy and quality in the manufacturing of different components. Milling, turning, and drilling are some of the machining processes where precision is crucial to determine the exact dimensions and tolerances of the final product. Precision machining is vital for meeting strict quality standards and ensuring optimal performance, from automotive parts to aerospace components. Join us as we delve into the significance of precision in machining and its influence on manufacturing success.

Key Points:

- Precision machining makes sure things work perfectly. So, you get top-notch products that last longer and work better.

- Precise machining ensures parts fit properly and work right.

- High-precision machining minimizes defects and failures. It leads to superior product quality.

- Consistent precision machining increases production efficiency and reduces waste.

- Precision machining is vital for industries like medical devices, electronics and aerospace.

Why Precision Matters in Machining

Precision in machining goes beyond just looking good. It directly affects a part’s ability to perform its intended function. When precision turned components are machined to exact specifications, they fit together seamlessly in assemblies. Exact measurements are crucial for things to work properly. If things aren’t made just right, they might not fit together correctly or work properly. It can even lead to breakage.

Think about a car engine. The parts inside, like pistons and valves, have to fit together just right so the engine runs smoothly and has enough power. If they don’t fit perfectly, it can make the engine work harder, use more fuel, and even break down.

Achieving high product quality is another reason why precision machining is so important.

When things aren’t made precisely during machining, it can lead to problems like scratches on the surface, wrong sizes, or weak spots inside. These problems can make the product weaker, less durable, and not work as well overall. In some cases, they can even lead to safety hazards, particularly in critical applications.

Benefits of Precision Machining

The advantages of precision machining extend far beyond just creating accurate parts. Here are some of the key benefits manufacturers experience:

1. Improved product performance and reliability

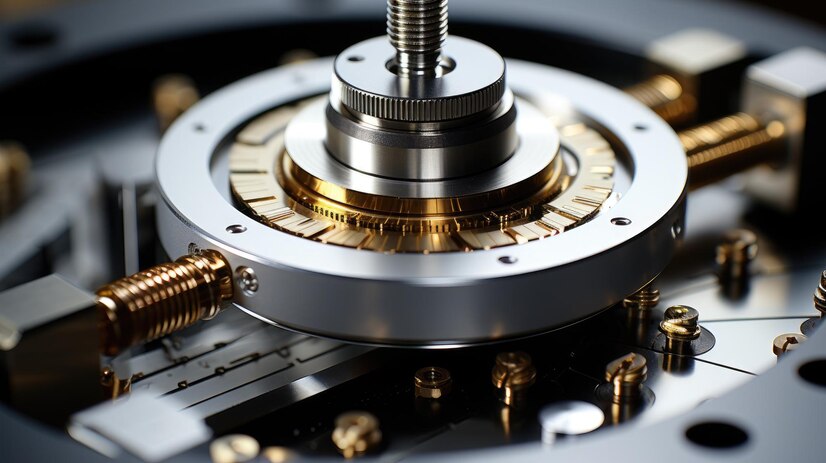

Precision components manufacturers produce precisely machined components that function flawlessly. This leads to reliable and dependable products. Take a complex machine tool for example.

The detailed gears, shafts, and bearings in machines need precise machining to work smoothly, move correctly, and keep working well for a long time.

2. Reduced costs

Minimized scrap, rework, and rejects translate to significant cost savings. In traditional machining, even minor inaccuracies can render parts unusable.

Precision machining saves materials and cuts down on extra work, which saves money.

When parts fit together perfectly, it means less fixing and adjusting during assembly, making production smoother and cheaper.

3. Faster time to market

Precision components manufacturers benefit from precision machining because it helps them make things faster.

In today’s fast-moving markets, speed matters a lot. Precision machining ensures that things are made correctly every time.

Thus, manufacturers don’t have to spend time fixing errors. This lets them meet deadlines and take advantage of market opportunities.

4. Enhanced brand reputation

When a company always makes really good stuff, people start to trust that brand more. Precision machining helps a lot with this by making sure all the parts are just right, so the products work well every time.

When customers know they can always rely on a brand, they’re happier and more likely to keep buying from them.

Applications Requiring High Precision

Certain industries depend a lot on precision machining. They need it to meet really important standards for how well their products perform and how safe they are. Here are some key examples:

1. Aerospace components

Precision turned components, like those used in aircraft parts, need to be made just right to keep the plane safe when it flies. Things like the wings, body, and engine parts have to fit perfectly because they go through a lot of stress when the plane is in the air.

If these parts aren’t made with precision, it could put the plane at risk of serious problems.

That’s why precision machining is crucial to make sure everything meets the high standards needed for safe and dependable air travel.

2. Medical devices

In medical stuff like implants and surgical tools, it’s super important for everything to be just right. Things like artificial joints or pacemakers have to fit perfectly in the body to work well and keep patients safe.

Precision machining is what makes sure these devices are made with the exactness needed to do their job perfectly every time.

3. Electronics

Making precision turned components for electronic devices like smartphones and computers needs really careful machining. These devices have super tiny parts, like microchips and connectors, which needs cautious attention.

If they’re even a little bit off, they might not work properly. This may cause problems like short circuits or signal issues.

Precision machining helps make sure these small parts are made accurately to make your electronic devices work reliably.

4. Automotive components

Precision turned components are super important for cars to work safely and well. Think about the engine in a car. The parts inside, like pistons and valves, have to fit together just right so the engine runs smoothly and doesn’t use too much fuel.

Also, parts in the steering and suspension need to be made precisely for the car to handle safely.

Nowadays, with more automated features in cars, precision machining is even more critical to make sure things like driver-assistance systems work reliably.

Final Thoughts

Making things with precision is super important in modern manufacturing. When parts are made exactly as they should be, it helps make better quality products, makes production faster, and helps different industries succeed.

Ganesh Precision: Your Partner in Manufacturing Excellence

Ganesh Precision is a leading manufacturer of precision turned components in India. We understand the critical role of precision machining. So, we work hard to make sure every part we make is top-notch. Our team of experts uses really high-tech machines and checks everything carefully to make sure your parts are exactly what you need.

At Ganesh Precision, we pride ourselves on delivering unmatched precision. We promise tolerances down to really tiny measurements, so the parts work perfectly every time. Our focus on getting things just right means you get reliable and long-lasting parts.

We also work efficiently to make sure you get your parts when you need them. Using advanced methods, we speed up production and make sure your parts arrive on time.