Introduction

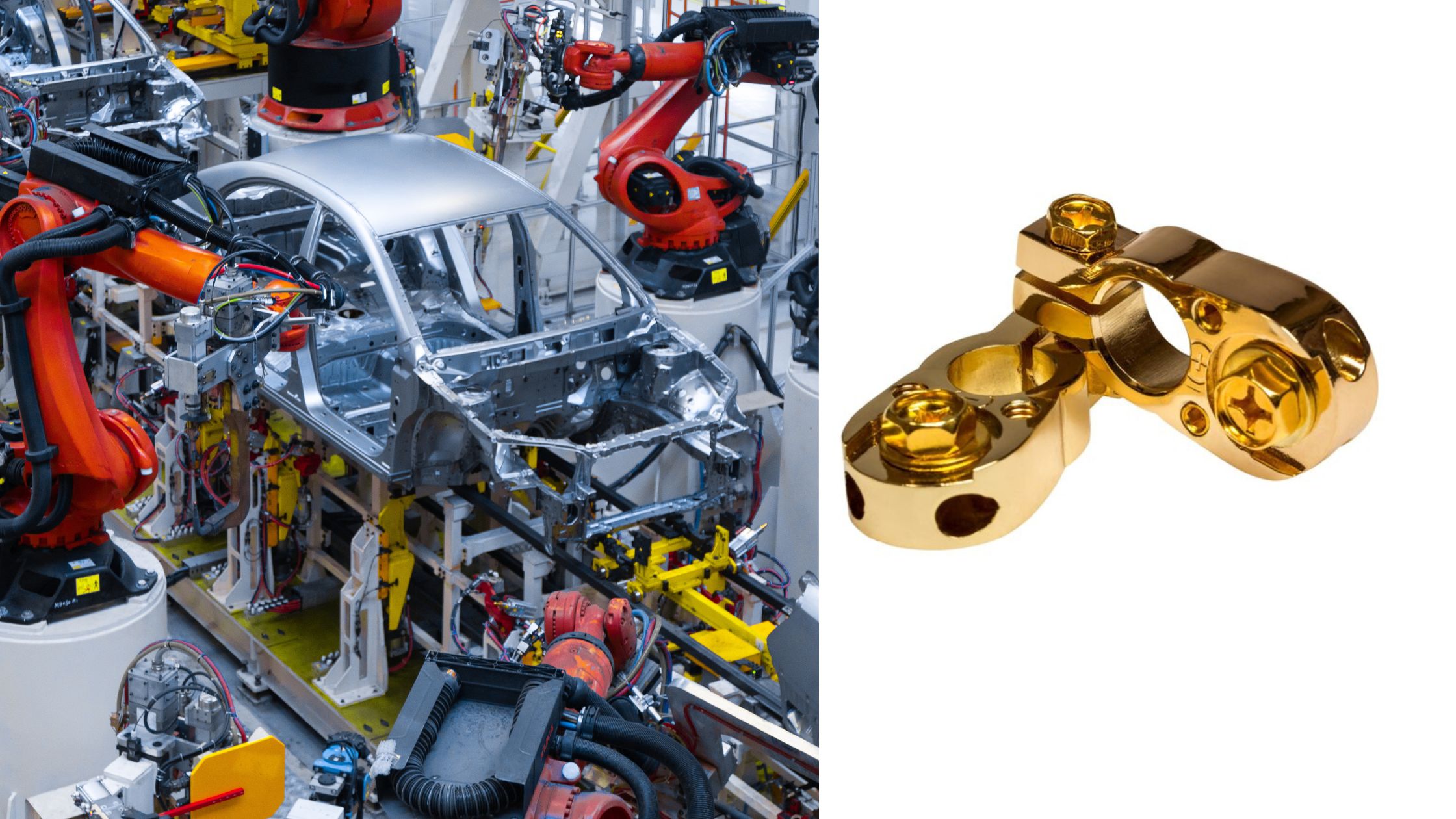

In the automotive manufacturing industry, choosing the right materials for vehicle components is crucial. One such material is brass. Brass is an alloy primarily composed of copper and zinc, with the proportion of each metal varying to achieve different properties. It is widely used in many industries, including automotive manufacturing. Brass parts manufacturers in Jamnagar have played a key role in supplying high-quality brass components. These components meet the growing demands of the automotive sector. This blog will explore the advantages of using brass in automotive manufacturing and how it improves vehicle performance.

Key Takeaways

- Brass components are highly durable, making them ideal for critical automotive parts. Brass parts manufacturers in Jamnagar ensure long-lasting, reliable solutions.

- Brass parts manufacturer provide components with exceptional thermal and electrical conductivity. This improves the efficiency of automotive systems.

- Brass components resist corrosion, even in harsh environments. Brass components manufacturers in Jamnagar deliver parts that last longer and require less maintenance.

- Brass is fully recyclable and sustainable. Brass parts manufacturers focus on producing environmentally friendly automotive components.

What is Brass and Its Components?

Brass is a non-ferrous alloy made from a combination of copper and zinc. TThe ratio of copper to zinc can vary, creating different types of brass alloys. This variation allows manufacturers to tailor the material’s properties to specific applications. Brass is known for its durability, corrosion resistance, and aesthetic appeal, making it an ideal choice for automotive parts.

What are the Advantages of Brass?

Brass offers a range of benefits that make it a popular choice in the automotive industry. Below are the top five advantages of using brass in automotive manufacturing.

1. Superior Corrosion Resistance

One of the most significant advantages of brass is its excellent corrosion resistance. Brass does not easily rust or corrode when exposed to moisture, chemicals, or harsh environments, making it an ideal material for automotive parts exposed to various weather conditions. Brass components used in automotive systems are less likely to degrade over time, ensuring longevity and reliability. This is particularly beneficial in parts like radiators, fuel systems, and engine components, where durability is critical.

2. Exceptional Thermal and Electrical Conductivity

Brass exhibits exceptional thermal and electrical conductivity. In automotive manufacturing, this is especially important in components like electrical connectors, switches, and sensors. Brass parts manufacturer provide components that can effectively handle heat dissipation, preventing overheating of electrical systems. This conductivity also helps improve the performance of batteries and electrical circuits, enhancing overall vehicle functionality.

3. Durability and Strength

Brass is known for its strength and durability, making it an ideal material for automotive parts that undergo significant wear and tear. The alloy is strong enough to withstand mechanical stress, yet flexible enough to be molded into intricate shapes. Brass components manufacturers in Jamnagar produce parts that maintain their structural integrity even under high-pressure conditions. This combination of strength and durability is vital for components like brake fittings, valve stems, and fasteners, which need to perform reliably throughout the life of the vehicle.

4. Lightweight and Cost-Effective

Brass is a relatively lightweight material compared to other metals like steel or iron. This makes it suitable for applications where weight reduction is crucial, such as in the engine, suspension, and transmission systems. Lighter vehicles consume less fuel, improving overall fuel efficiency. Additionally, brass is cost-effective in the long term due to its durability and low maintenance needs. Brass parts manufacturer in Jamnagar produce brass components that provide excellent value for money without compromising on quality or performance.

5. Eco-Friendly and Sustainable Material

Brass is an environmentally sustainable material because it is fully recyclable. Using brass in automotive manufacturing reduces the need for raw materials and minimizes environmental impact. The recycling process for brass is energy-efficient, further enhancing its eco-friendliness. As the automotive industry moves toward more sustainable practices, brass components can play a key role in achieving these goals by contributing to the reduction of waste and energy consumption.

6. Aesthetic Appeal and Customizability

Brass has a natural golden hue that adds an aesthetic appeal to automotive components. This visual attractiveness is one reason why brass is used in both functional and decorative parts, such as trim, badges, and decorative fasteners. Also, brass components can be customized to meet the specific design requirements of a vehicle, providing flexibility in production. Whether for visual appeal or for functional purposes, brass offers a versatile material choice for automotive manufacturers.

Which Brass Parts are Used in the Automotive Industry?

Brass is used in a wide range of automotive applications due to its diverse properties. Some common brass parts found in vehicles include:

- Electrical connectors and terminals

- Fuel system components

- Brake fittings

- Valve stems and seat inserts

- Radiators and heat exchangers

- Fasteners and bolts

- Trim and decorative elements

These parts benefit from brass’s corrosion resistance, strength, and thermal conductivity, making them suitable for critical automotive functions.

Applications of Brass in the Automotive Industry

Here is a list of applications where brass is commonly used in automotive manufacturing:

- Electrical Connectors: Brass is widely used in electrical connectors because of its excellent conductivity and resistance to corrosion.

- Fuel System Components: Brass is often used for fuel lines, fittings, and valves due to its resistance to corrosion from fuels and chemicals.

- Engine Parts: Brass components like valve stems and seat inserts offer durability and thermal conductivity to withstand high temperatures.

- Brake Fittings: Brass is used in brake systems due to its strength and resistance to wear, ensuring reliability in high-stress situations.

- Trim and Decorative Parts: Brass adds an aesthetic appeal to cars through trim, badges, and other decorative components, enhancing the vehicle’s overall look.

Innovations and Future of Brass in Automotive Manufacturing

As the automotive industry evolves, the demand for sustainable, durable, and high-performance materials continues to grow. Brass is well-positioned to meet these challenges, thanks to its recyclability, durability, and versatility. Innovations in alloy compositions are making brass even more suitable for use in advanced automotive technologies, such as electric vehicles (EVs). Furthermore, developments in manufacturing techniques are enabling brass components manufacturers to produce more cost-effective and precise parts.

The future of brass in automotive manufacturing looks bright, with new applications emerging in electric vehicle batteries, lightweight vehicle structures, and more. As manufacturers continue to push the boundaries of automotive design and efficiency, brass will remain a vital material in meeting these demands.

“Brass is a highly versatile and durable material that plays a crucial role in automotive manufacturing. Its superior corrosion resistance, excellent thermal and electrical conductivity, strength, lightweight nature, eco-friendliness, and aesthetic appeal make it an ideal choice for various automotive parts. Brass parts manufacturers and brass components manufacturers in Jamnagar continue to produce high-quality products that enhance vehicle performance and longevity.

If you’re looking for high-quality brass components for automotive manufacturing, Ganesh Precision, a leading brass components manufacturer in Jamnagar, offers reliable and cost-effective solutions. Ganesh Precision is a renowned brass components manufacturer in Jamnagar, specializing in high-quality, precision-engineered brass parts. With a commitment to excellence, we offer durable, reliable, and cost-effective solutions for various industries, including automotive. Our expertise ensures superior performance and customer satisfaction with every product they deliver. Looking for high-quality brass components? Contact Ganesh Precision today for reliable solutions and exceptional service!’’

FAQs

Why is Brass Used in Manufacturing?

Brass is used in manufacturing due to its excellent corrosion resistance, strength, conductivity, and ease of fabrication. It is also highly durable and can withstand harsh environmental conditions.

What are the Common Brass Alloys Used in Automotive Manufacturing?

Common brass alloys in automotive manufacturing include yellow brass, red brass, and high-strength brass, depending on the required properties like corrosion resistance and strength.

What are the Components of the Automotive Industry?

The components of the automotive industry include vehicle parts such as engines, transmissions, electrical systems, suspension systems, and body parts, along with raw materials used in their production.

Where is Brass Used on a Car?

Brass is used in various parts of a car, including electrical connectors, fuel system components, brake fittings, engine parts, and decorative elements.