Introduction

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by enabling high precision and automation in the production process. These machines are made up of several intricate parts, each playing a crucial role in ensuring efficient and accurate operations. Understanding the major CNC components is essential for manufacturers to optimize machine performance and produce high-quality CNC turned components. In this blog, we explore the seven key parts of a CNC machine.

Key Takeaways

- CNC machines consist of several key CNC components. These parts work together for precision machining.

- CNC turning parts are vital for creating precise shapes and sizes in different materials.

- CNC turned components require high-quality machinery and skilled manufacturers for accuracy.

- Understanding CNC turning machine parts can enhance efficiency and improve production output.

What is a CNC Machine?

A CNC machine stands for Computer Numerical Control machine. It is an automated tool used for machining various materials like metals, plastics, and wood. The operation of CNC machines is controlled through a computer system, which allows precise control over the movement of the machine and its components. The system translates a computer-aided design (CAD) into a numerical code that guides the machining process. This leads to high precision, consistency, and the ability to handle complex tasks.

Why is Understanding CNC Machine Parts Important?

Understanding the parts of a CNC machine is crucial for operators, engineers, and manufacturers to ensure efficiency, accuracy, and reliability in the production process. Each CNC component plays a distinct role in the overall functionality of the machine. Knowledge of these parts helps in troubleshooting, maintaining the machine, and improving its performance.

7 Major Parts of a CNC Machine

CNC machines are composed of several components that work in unison to achieve precise machining. Below are the seven major parts of a CNC machine:

- CNC Controller – The CNC controller is the brain of the machine. It takes input from a computer program and translates it into electrical signals that control the movement of the CNC turning parts. The controller ensures that the machine operates according to the specifications, resulting in accurate machining.

- Drive Motors and Servo Motors – These motors are responsible for powering the movement of the CNC turned components. The motors drive the axes of the machine (X, Y, Z axes in most cases), allowing the cutting tools to move accurately along the workpiece. These motors are high-performance components that ensure the speed and precision of operations.

- Machine Tool Spindle – The spindle holds the cutting tool in place and rotates it at high speeds during the machining process. It is essential for cutting, shaping, and drilling materials. The spindle is designed to handle various CNC turning machine parts like drills, lathes, and mills, which are used to cut through materials precisely.

- Tool Holder – The tool holder securely holds the cutting tool in position during the machining process. Tool holders are available in different types to accommodate various tools used in CNC turning. The stability and accuracy of the tool holder directly affect the quality of the final CNC turned components.

- Linear Guides – Linear guides are critical for smooth and precise movement of the machine along its axes. These guides help the machine’s moving parts glide with minimal friction, ensuring that the CNC turned parts are produced to the required specifications. They are essential for the accuracy and longevity of the machine.

- Workpiece or Material Fixture – The workpiece fixture holds the material in place during the machining process. It ensures that the workpiece remains stable and aligned with the cutting tools. Accurate fixtures are essential for ensuring that the CNC turning parts are cut to the correct size and shape.

- Coolant System – The coolant system is responsible for keeping the cutting tool and the workpiece cool during the machining process. High-speed cutting generates heat, and the coolant helps reduce this heat to avoid damage to both the tool and the workpiece. It also helps in removing debris from the cutting area, improving the efficiency and lifespan of the machine.

How CNC Machine Works?

A CNC machine operates based on instructions programmed through a CNC component. The process begins by creating a 3D model using CAD software. The model is then converted into a CNC-compatible program, often in G-code. This program directs the movements of the CNC turning machine parts and guides the cutting tools to perform the required actions. The machine then uses its motors and controllers to move the tools across the material, shaping it into the desired form. Leading CNC turned components manufacturers, ensures precision in every step of this process.

How Do These Parts Work Together?

Each of the CNC components plays a vital role in ensuring the machine works efficiently. The CNC controller translates the program into signals for the motors, which move the tool along the material. The tool holder keeps the cutting tool in place while the machine tool spindle rotates it at high speeds. The workpiece fixture holds the material steady, and the coolant system ensures that the process runs smoothly by maintaining the right temperature. Together, these parts contribute to the accuracy and precision required to create high-quality CNC turned components.

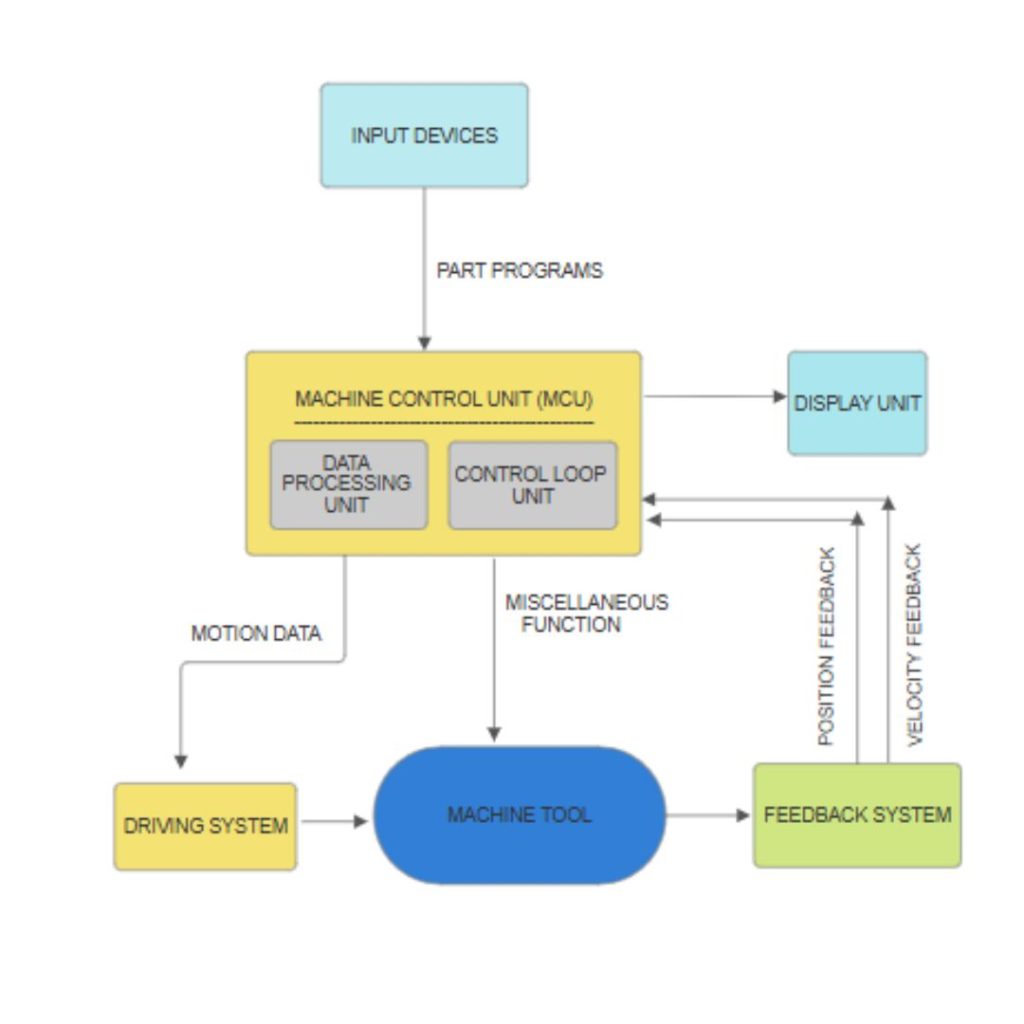

CNC Machine Block Diagram

Explanation:

- CNC Controller: Receives input from the CNC program (usually G-code) and directs the machine’s movements.

- Drive Motors & Servo Motors: These motors drive the machine’s axes, moving the cutting tool or workpiece to desired locations.

- Spindle Motor: Rotates the cutting tool at high speeds for machining processes.

- Tool Holder: Holds and stabilizes the cutting tool during operation.

- Linear Guides: Provide smooth motion for the machine’s moving parts, ensuring accuracy.

- Workpiece Fixture: Secures the material in place for precise machining.

- Coolant System: Cools the cutting area to prevent overheating and removes debris.

This block diagram highlights the major CNC components that work in harmony to ensure accurate and efficient machining.

“CNC machines are intricate systems made up of several CNC components that work together to produce high-quality parts. The seven major parts – the controller, drive motors, spindle, tool holder, linear guides, workpiece fixture, and coolant system are essential for the machine’s functionality. Understanding how these parts interact can help optimize the machining process, leading to better-quality CNC turned parts. For high-precision needs, working with an experienced CNC turned parts components manufacturer is essential for achieving the best results.

If you are looking for a reliable partner to supply high-precision CNC turned components, Ganesh Precision is the ideal choice. At Ganesh, we specialize in manufacturing high-quality CNC turned components tailored to meet the specific needs of our clients. With a strong focus on precision and reliability, we use advanced technology and skilled craftsmanship to produce parts that meet the highest industry standards. Our commitment to innovation and quality ensures that every CNC turning part we deliver performs with durability and accuracy, making us a trusted partner in the industry.

If precision and quality matter to you, Ganesh Precision is here to deliver the CNC turned components your business needs. Our expertise and commitment to excellence will ensure your projects are completed with unmatched accuracy. For tailored solutions and reliable service, contact us today!”

FAQs

What are CNC machine parts?

CNC machine parts are the various components that make up a CNC machine. They include the controller, drive motors, spindle, tool holder, linear guides, workpiece fixture, and coolant system.

What is CNC Turning?

CNC turning is a machining process that involves rotating a workpiece while a cutting tool shapes it. It is used for producing CNC turning parts with high precision.

What does CNC Machine stand for?

CNC stands for Computer Numerical Control. It refers to machines controlled by a computer program to perform precise machining operations.

What are the basic CNC components?

The basic CNC components include the controller, motors, spindle, tool holder, and guides. These parts help in carrying out the machining tasks.

What are CNC machine tools?

CNC machine tools refer to the tools used in CNC machines for cutting, drilling, or shaping materials. They are essential for producing CNC turned components.

What is CNC and how do they all work together?

CNC (Computer Numerical Control) machines use computer programs to control the movement of parts like the spindle, motors, and tool holders. These parts work together to produce precise CNC turned parts.