Understand the potential of brass with this guide. Explore common brass components, their benefits, and why they’re the go-to choice for many applications.

Introduction

Brass, a versatile and durable alloy, plays a crucial role in various industries; moreover, this is due to its unique properties. Comprising primarily of copper and zinc, brass components are essential in manufacturing, construction, and many other sectors. Understanding the main brass components and their advantages can help industries make informed choices, enhancing efficiency and product longevity. This blog explores the key brass turned parts, their variations, uses, and benefits.

Key Takeaways

- Brass is a versatile alloy of copper and zinc, offering a balance of strength, ductility, and corrosion resistance.

- Brass parts manufacturer make brass components from alloy brass. It consists primarily of copper and zinc, known for their durability, corrosion resistance, and versatility in various applications.

- Common brass components include pipes, fittings, valves, and electrical connectors, valued for their durability and machinability.

- Brass, therefore, provides superior resistance to dezincification compared to other metals. It is a form of corrosion that can weaken components.

- The specific advantages of brass components, however, depend on the type of brass used, such as, for instance, increased lead content for improved machinability.

A Look at The Key Brass Components

- Brass Rods: Used in various machining and construction applications, brass rods are known for their strength and corrosion resistance.

- Brass Sheets: Ideal for decorative and architectural applications. Brass components manufacturers produce brass sheets with aesthetic appeal along with durability.

- Brass Tubes: Commonly used in plumbing and heating systems, brass tubes offer excellent thermal conductivity and corrosion resistance.

- Brass Fittings: Essential in plumbing and electrical systems, brass fittings ensure leak-proof and durable connections.

- Brass Valves: Used in fluid control systems, brass valves offer reliable performance and longevity.

- Brass Fasteners: Brass screws, nuts, and bolts are used in various applications for their resistance to corrosion and appealing finish.

- Brass Electrical Components: Brass is a preferred material in electrical components. It is due to its conductivity and durability.

- Brass Hinges: Brass manufacturers in India know the diverse needs of brass components. It is often used in furniture and architectural applications; brass hinges provide strength and aesthetic appeal.

Exploring Brass Components Variation and Its Uses

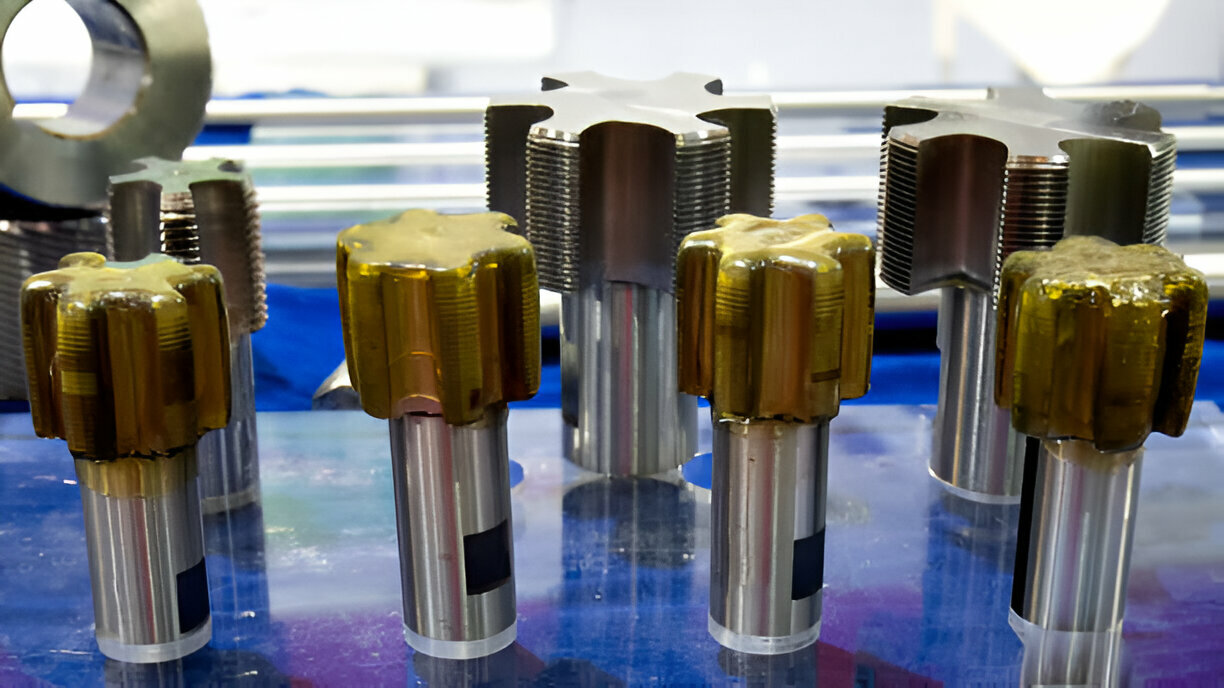

- Free Cutting Brass: Contains a small amount of lead, making it easier to machine. Commonly used in precision components such as gears and valves.

- High Tensile Brass: Includes additional elements like iron, making it stronger. Used in heavy-duty applications like marine hardware and pump shafts.

- Admiralty Brass: Contains tin, enhancing corrosion resistance. Often used in naval applications and heat exchangers.

- Muntz Metal: A type of brass turned parts with a higher zinc content. Used in sheathing for ship hulls and architectural panels.

- Aluminum Brass: Contains aluminum for enhanced strength and corrosion resistance. Used in condenser tubes and automotive applications.

- Naval Brass: Includes tin and zinc for improved resistance to seawater corrosion. Common in shipbuilding and marine hardware.

- Lead-Free Brass: Developed for applications requiring lead-free materials, such as drinking water systems and food equipment.

Advantages of Brass Components

- Durability: Brass components manufacturers make brass components that have a long lifespan. This is due to their high durability and resistance to wear and tear.

- Corrosion Resistance: Brass does not corrode easily. This makes it ideal for applications exposed to moisture and chemicals.

- Thermal Conductivity: Brass has excellent thermal conductivity. It is crucial for heat exchange and plumbing systems.

- Electrical Conductivity: Brass is a good conductor of electricity. It makes brass turned parts suitable for electrical components and fittings.

- Malleability: Brass is easy to shape and mold, allowing for the creation of intricate designs and precise components.

- Aesthetic Appeal: Brass has a distinctive golden hue. Hence, making it a popular choice for decorative items and architectural elements.

- Recyclability: Brass is fully recyclable, which contributes to sustainable manufacturing practices and reduces environmental impact.

- Non-Sparking Properties: Brass does not produce sparks when struck, making it safe for use in explosive environments.

Why Choose Ganesh Precision?

Ganesh Precision stands out as a leading manufacturer of brass components. Here’s why:

- Quality Assurance: Ganesh Precision ensures the highest quality standards for all its brass components. We adhere to rigorous quality control measures.

- Customization: We offer customized solutions to meet specific requirements. Our tailored brass components is used for diverse applications.

- Advanced Technology: Utilizing state-of-the-art technology and machinery, we manufacture precise and reliable brass components.

- Expertise and Experience: With years of experience and expertise in the industry, Ganesh Precision has a deep understanding of brass component manufacturing.

- Sustainability: We are committed to sustainable practices. Thus, ensuring that their manufacturing processes are environmentally friendly.

- Customer Support: We provide excellent customer service, assisting clients with technical support and after-sales services.

Conclusion

Brass components are indispensable in many industries due to their remarkable properties and versatility. From brass rods and sheets to valves and electrical components, each type serves a specific purpose, offering durability, corrosion resistance, and aesthetic appeal. Our commitment to quality, advanced technology, and customer satisfaction, manufactures the best brass components in the market. Choose Ganesh Precision for reliable, high-quality brass components that meet your needs.

FAQs

1. What are the disadvantages of brass metal?

Brass can be prone to dezincification, which is the selective leaching of zinc in certain environments, weakening the material. It is also relatively soft compared to other metals, which may limit its use in high-stress applications.

2. What is the most common composition of brass?

The most common composition of brass is an alloy of copper and zinc, typically in a 60:40 ratio, although this can vary depending on the specific type of brass.

3. What is the formula for brass?

Brass does not have a specific chemical formula because it is an alloy, not a compound. Its composition is generally expressed as CuZn, representing copper (Cu) and zinc (Zn).

4. What is the alloy of brass?

Brass is an alloy primarily composed of copper and zinc. Other elements like lead, tin, aluminum, and iron may be added to enhance specific properties for different applications.